- Home

- Technical

Technical

Fluoropolymers generally exhibit a range of similar properties due to their unique chemical composition. They are typically resistant to both extreme high and low temperatures, chemically inert, do not degrade and possess an extremely low coefficient of friction.

Fluoropolymers generally exhibit a range of similar properties due to their unique chemical composition. They are typically resistant to both extreme high and low temperatures, chemically inert, do not degrade and possess an extremely low coefficient of friction.

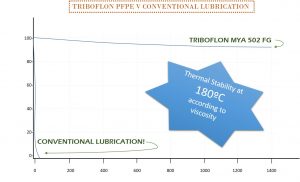

PFPE’s (fluorinated lubricants) offer a unique range of properties, significantly outperforming conventional lubricants and delivering unsurpassed durability. In general, TRIBOFLON PFPE lubricants should be considered when other lubricants reach their limitations, are failing for some reason or when a long service life is required i.e. ‘lubricated for life’ applications.

TRIBOFLON PFPE oils and greases perform where hydrocarbon (petroleum) based lubricants and other synthetic lubricants fail because of PFPE’s unique chemical nature and inherent properties.

Stability in extremes of temperature

Extreme temperature stability, with operating ranges from –90 to 350 °C (–103 to 662 °F) and as high as 400 °C (752 °F) with appropriate metallurgy

Extreme temperature stability, with operating ranges from –90 to 350 °C (–103 to 662 °F) and as high as 400 °C (752 °F) with appropriate metallurgy- Thermally stable

- Will not carbonise

- Low volatility – extremely low evaporation

Bearing Comparison Test

TRIBOFLON PFPE Greases offer lifetime lubrication of bearings. Some other greases have significantly larger particles which can increase wear, noise and contribute to premature bearing failure whereas the extremely fine, sub micron particles of special PTFE provide a very uniform lubricating film preventing wear and resulting in lifetime lubrication.

TRIBOFLON PFPE Greases offer lifetime lubrication of bearings. Some other greases have significantly larger particles which can increase wear, noise and contribute to premature bearing failure whereas the extremely fine, sub micron particles of special PTFE provide a very uniform lubricating film preventing wear and resulting in lifetime lubrication.

Chemically Inert

TRIBOFLON performance lubricants are inert to virtually all chemicals used in a variety of industries. They are insoluble in most solvents, acids and aggressive chemicals. For cleaning we have special fluorinated cleaners which can remove these products or be used to disperse them for ease of application.

Biologically Inert

Ideal for clean room or medical environments where Infection Prevention and Control is an essential aspect of equipment being fit for purpose and maintained to a high standard, TRIBOFLON PFPE lubricants are classified as non-toxic, biologically inert and fully compliant with Health and Safety control measures.

It is safe to use with all metals, plastics, leather, elastomers and seal materials and is totally non-flammable. Some TRIBOFLON PFPE lubricants are NSF registered for use in food environments.

Non-Migratory

In the electronics industry, damping greases (high-viscosity lubricants) are used to provide drag and give switches a “high-quality” feel. Although silicones historically have been used as damping greases, TRIBOFLON PFPE offers a similar feel without fear of silicone migration, which is more than an aesthetic problem. Under arcing, silicone degrades to silicon dioxide (sand), an abrasive and insulating by-product that destroys contacts quickly.

Non-Flammable

Standard TRIBOFLON lubricants contain only carbon, oxygen, and fluorine; whereas, hydrocarbons contain hydrogen. The absence of hydrogen greatly increases the stability of the lubricants and renders them non-flammable with no flash point. They will not burn or support combustion, even in an environment of 100% liquid or gaseous oxygen.

Standard TRIBOFLON lubricants contain only carbon, oxygen, and fluorine; whereas, hydrocarbons contain hydrogen. The absence of hydrogen greatly increases the stability of the lubricants and renders them non-flammable with no flash point. They will not burn or support combustion, even in an environment of 100% liquid or gaseous oxygen.

At elevated temperatures and pressures, PFPE oils are highly resistant to attack by gaseous and liquid oxygen. Conventional lubricants that contain mineral oils or conventional synthetics can react with oxygen and halogens, such as chlorine, fluorine, and bromine; thus, increasing the potential for explosion, fire, and premature deterioration. Reactive gas applications require lubricants that help provide safe operations.

Electrical Properties

TRIBOFLON PFPE lubricants prevent wear whilst maintaining electrical continuity, without fear of silicone migration and able to withstand extremes of temperatures. With extremely high compatibility only PFPE lubricants are inert enough to be considered safe with practically every component and seal.

TRIBOFLON PFPE lubricants prevent wear whilst maintaining electrical continuity, without fear of silicone migration and able to withstand extremes of temperatures. With extremely high compatibility only PFPE lubricants are inert enough to be considered safe with practically every component and seal.

TRIBOFLON PFPE leaves no insulating residue and long-life prevents arcing.